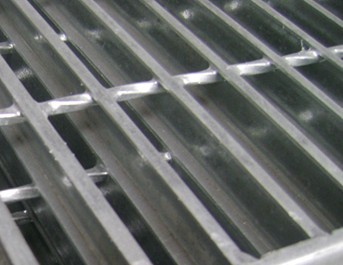

Channel steel grating

Channel steel grating provides a simple structure, easy production, scientific and rational groove timber steel grill plate. It comprises a flat steel bar in accordance with a constant pitch and arrayed grating latitude, and welded to the intermediate square lattice, characterized in that the ends of the bearing bar hemming Movement [-shaped cold-formed channel the outer surface of the flanges of the beam on the grating grooves, the lower surface. Since the flat shape of the load beam is a groove, which groove hemming steel material is bent away from the center, the center axis of symmetry of the cross section, according to the formula modulus of the bending section, the moment of inertia of the cross-sectional shape with this much higher At the same moment of inertia of the cross-sectional area of flat steel. So, which is made of the same strength and stiffness than steel grating flat in selected materials can greatly reduce the weight also significantly reduced the use of materials more scientific and reasonable.

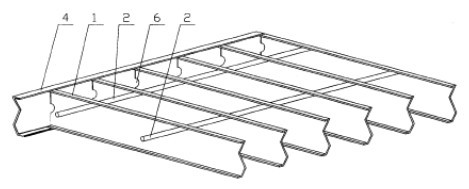

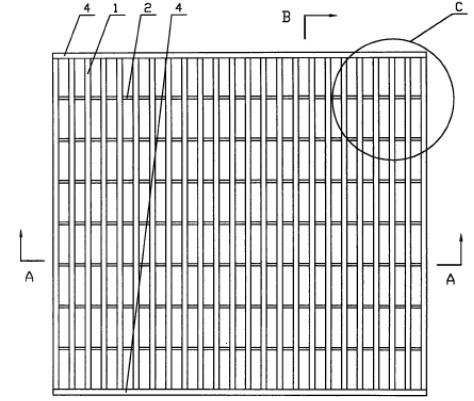

Channel steel grating structure diagram

Features channel

steel grating

A groove savings using

steel grid plate steel: subjected to the same load conditions most economical dosage plate, the material can be reduced correspondingly support structure.

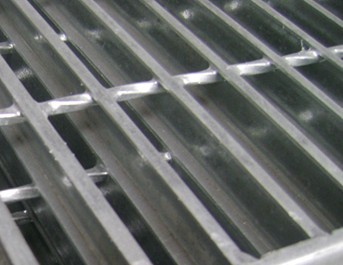

2, the appearance of the modern style: appearance, design specifications, air and light, giving the overall sleek, contemporary feel.

3, due ladders (stair treads) using a grid design so it can greatly reduce wind resistance: Due to good ventilation, in case of small wind drag, reducing wind damage.

4, CAD computer design is simple: no small beam, simple structure, designed to simplify; without grating design detail, you can only specify the model, customers can design factory layout diagram.

5 construction workers is simple: in the pre-installed on the supporting bolt clamping, a person can be completed.

6, can be greatly reduced investment: saving materials, labor, provincial period, free cleaning and maintenance.

7, the installation time is short, can greatly reduce the period: Products without on-site processing, installation is very fast.

8, durable: the factory hot-dip zinc corrosion treatment, corrosion resistance, is checkered multiples of use.

9, trough-shaped

steel mesh grating structure against product contamination: no accumulation of rain, snow and dust.

10, good ventilation, lighting, heat, explosion-proof, anti-slip properties.

Tank steel grating structure

Channel steel grating with conventional steel grating structures are similar, with the main flat steel edging and edging using welded rails with welded flat steel bar with the other carrier is perforated connection, and then welding fixed, polished Overall hot-dip galvanized, and then after finishing channel steel grating is finished. Fabricated channel steel gratings are lightweight versions of slot steel grill plate! Fabricated channel steel grating also has a high strength, money and material features, and lower prices! But no welded solid. Fabricated channel steel grating using the national standard galvanized steel processed into groove flat, flat as a master and edging, bar the use of M5 or M6 screw and casing, casing used to develop the grid spacing and fixed primary both ends of the flat steel screw with a nut fixed to intensify the main flat and riveted aluminum edging processed into finished channel steel gratings. Specific structure of the grid sheet steel channel as follows.

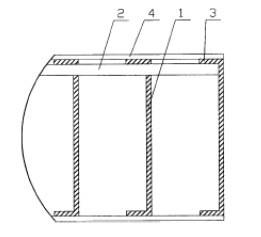

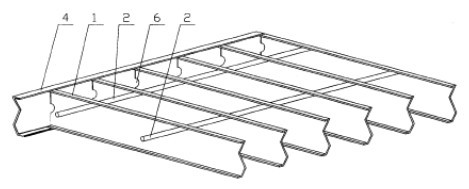

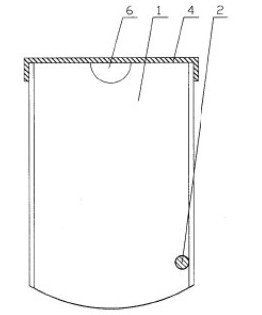

Channel steel grating side view of a side view

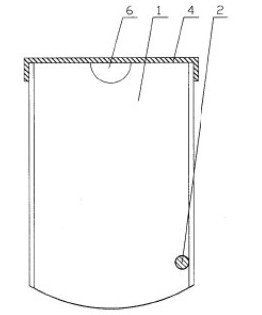

two slot-shaped steel grating

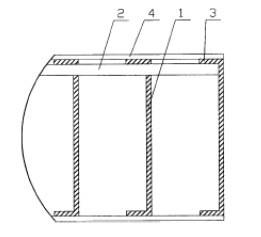

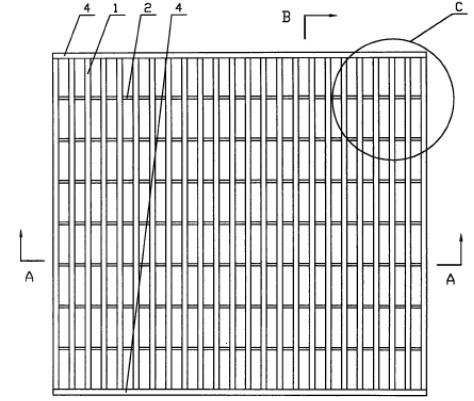

Channel steel grating front view

Description: 1, 2 load flat steel, square steel or twisted round three, cold-formed channel 4 hems, edging version 5, the through hole 6, flat gap